Seattle

Campus

Global Headquarters

Mammalian & Microbial Manufacturing Site

The Seattle campus has been producing biologics products for 30 years.

AGC Biologics operates multiple cGMP manufacturing lines and a variety of scales for mammalian and microbial biologics at our site. With a uni-flow design, the campus offers capacity and technological flexibility, including extensive adoption of single-use systems, while ensuring compliance with current ICH guidelines required for cGMP compliance. This location employs the latest fed-batch and perfusion manufacturing processes, and serves as our center of excellence for global formulation services.

Got a project? Let's talk!

Get all the details on this site.

Our in-depth fact sheet provides all the details you need on the complete capabilities and services of this campus and its abilities to support your next project.

DOWNLOAD NOWSeattle Campus Highlights

Hover over each card to learn more

Seattle Campus Highlights

Tap on each card to learn more

Mammalian Manufacturing

Our Mammalian manufacturing scale ranges from 100 L to 12,000 L, including stainless steel lines and single-use technology-based systems with fed-batch and perfusion manufacturing processes.

Microbial Fermentation Manufacturing

Our Microbial manufacturing features up to a 1,500 L, with opportunities for expansion. Our capabilities include protein analytics (GMP), IPC, and release testing.

Global Overview

Process Development

Full development service from lab development to commercial production including process transfer, cell line development, upstream and downstream development, process characterization and validation, and more.

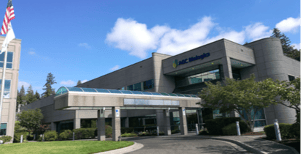

Research & Development Center

The Seattle site houses AGC Biologics’ global research and development center, where our scientists focus on modernizing and advancing our development and manufacturing capabilities worldwide. They are responsible for developing and implementing procedures that improve titers/yields, cell line development successes and more.

Expanded Warehouse

The expanded warehouse space to further safeguard products and materials. Our new 67,750 square feet building is fully segregated, with no shared utilities, large-scale freezing capabilities, and exclusive loading docks.

Watch our Seattle Campus Tour

Learn about our capabilities and expertise at our global headquarters facility.

Tour our new microbial manufacturing line in Seattle

Take a virtual walkthrough of our microbial production facility.

Explore our Seattle GMP Warehouse

Dive into our dedicated GMP warehouse that serves our Seattle site campus.

We Prioritize Environment, Health, & Safety Across All of Our Facilities

Our Seattle facility has achieved many certifications, including:

GLOBAL HEADQUARTERS

SEATTLE

T: +1-425-485-1900

F: +1-425-486-0300

E: contactus@agcbio.com

21511 23rd Dr. SE

Bothell, WA 98021 USA