1 min read

Key Considerations When Outsourcing Large-Scale Manufacturing

Nick McDonald December 8, 2023 at 6:29 AM

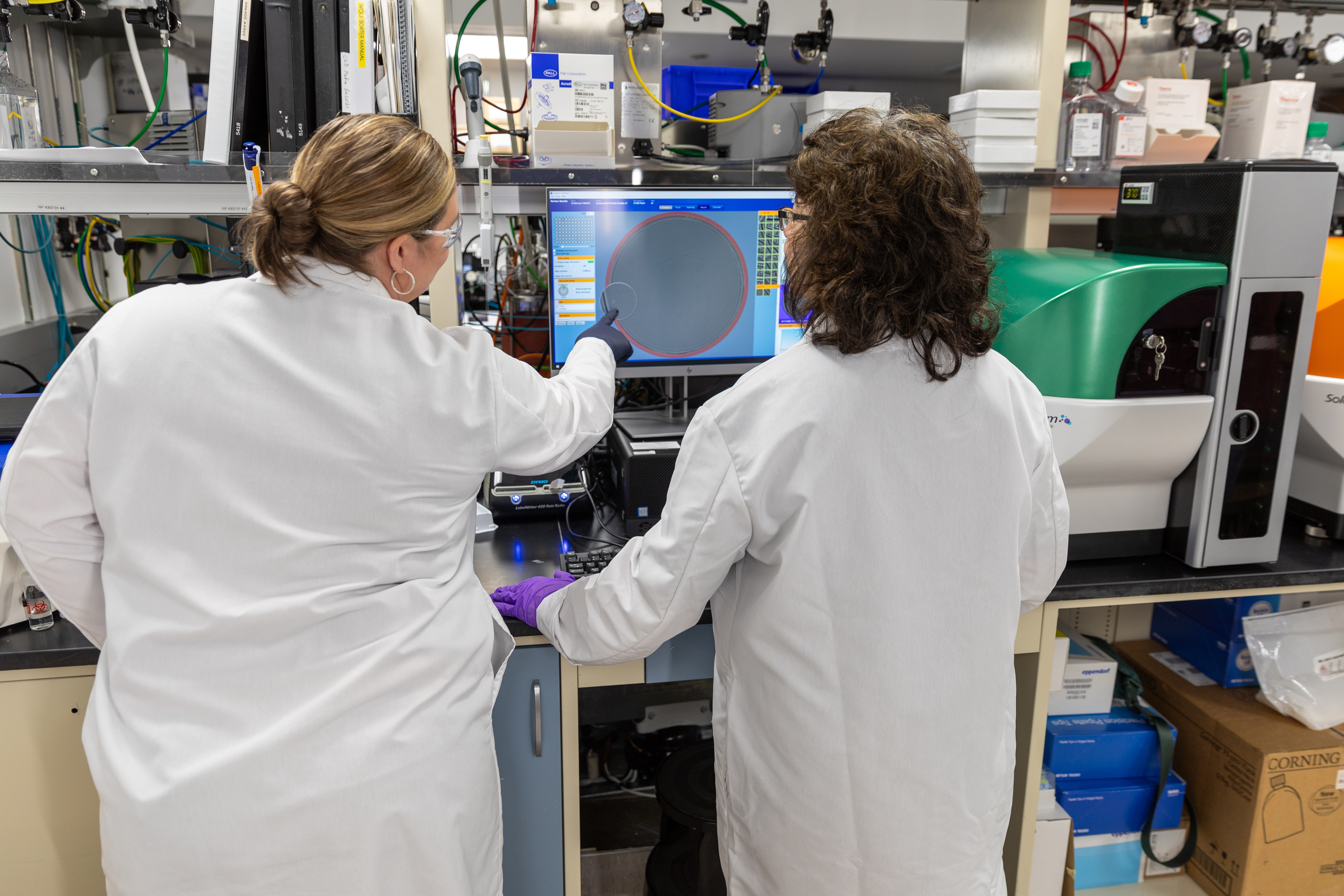

The decision to handle drug development and manufacturing in-house or outsource to a CDMO involves a complex evaluation of costs, timelines, production capacity, and available resources. Every customer, drug, and situation is different, requiring a careful consideration of the benefit-versus-risk equation.

In a recent educational white paper, Should you Outsource your Protein Biologics Product, AGC Biologics explored the considerations in this decision-making process. The discussion also explored the advantages of tapping into a CDMO's global network of scientific experience and resources for accelerated development, reduced risk, and cost-effectiveness.

If a company lacks internal capacity or needs to support a new product that doesn't align with future goals, outsourcing to a CDMO with available capacity is not only a viable alternative, but it gives you access to scientific minds that can navigate each critical product stage, while also offering you the opportunity to progress faster to your next clinical or commercial milestone.

Our white paper covers key factors for selecting a CDMO partner including evaluating the facility's capabilities, capacity within its global network, and ability to adopt various processes to meet your product's needs. If a CDMO is forcing to you conform to their platform without considering how that impacts the final product - they may not be the right fit.

Your next manufacturing partner should also demonstrate their understanding of the importance of proper assessments, risk analysis, and experience with the equipment that is needed to bring your product to its next stage. If the CDMO has the knowledge and experience to do these assessments well, it should be able to handle any new processes you bring them as a developer, no matter the stage of the product.

The decision to outsource drug development and manufacturing involves a thorough analysis of the outsourcing partner's capabilities, capacity, and adaptability to specific processes. Read our research and analysis and use it to help make your next outsourcing decision.

Interested in reading more?

Questions? Let's chat.

Learn more