1 min read

Video: How to Adapt Mammalian Manufacturing Strategies for Evolving Regulatory Expectations

Nick McDonald May 10, 2024 at 1:02 PM

Watch the full video from our subject matter expert below!

With regulatory approval requirements constantly evolving, AGC Biologics makes it a priority to continuously optimize processes to find the ideal balance between efficiency and risk management. In the video below, Mark Davis, Director of MSAT at AGC Biologics Boulder facility, talks about the challenges his team faces and how they use strategic planning and expertise to navigate a changing landscape while ensuring that the client, and more importantly, the patient receives these life saving products on time.

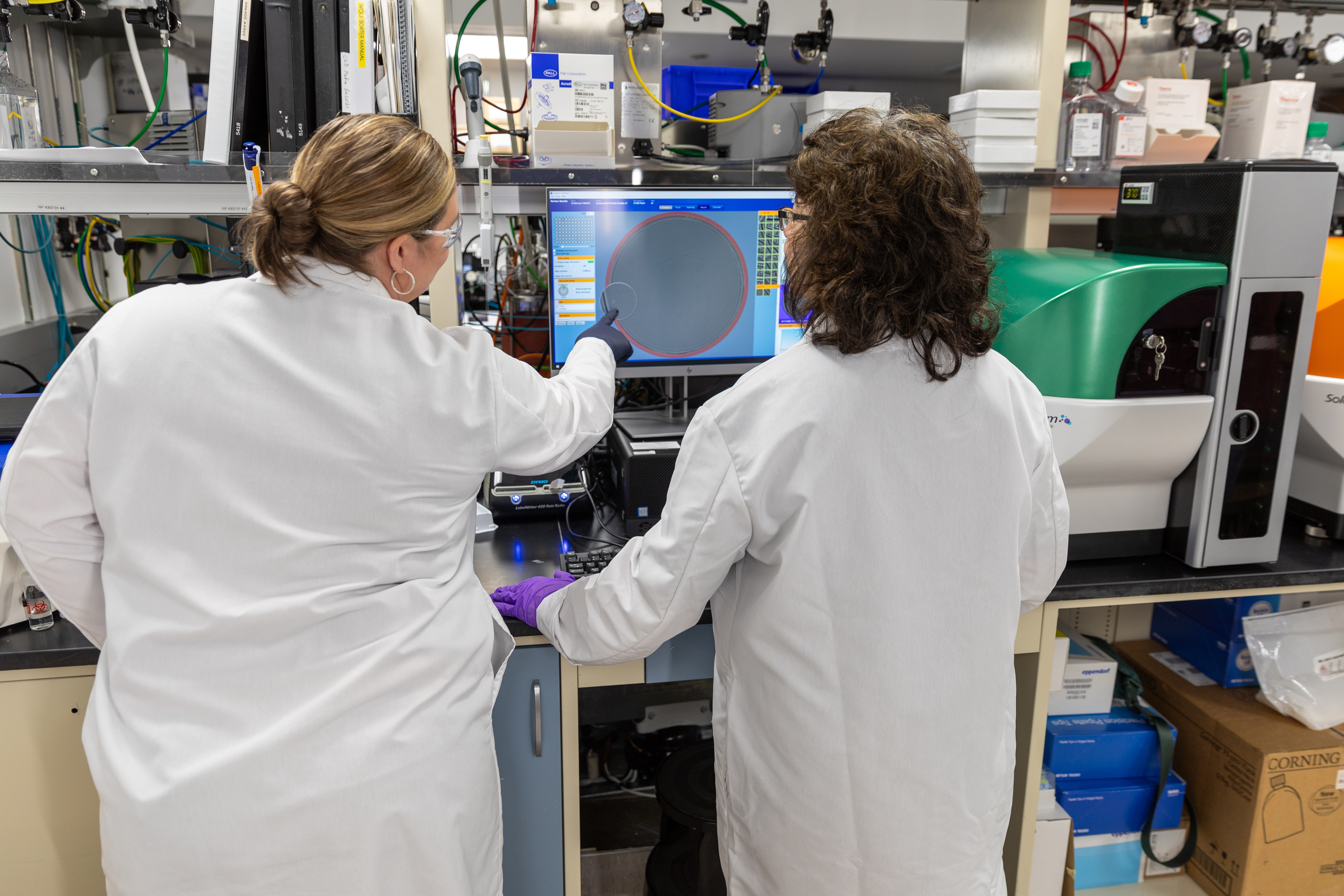

AGC Biologics Boulder facility is home to a large-scale commercial manufacturing line with two 20,000 L bioreactors, providing this site with the means to produce high-demand products quickly and effectively. However, when dealing with such large scale volumes, ensuring strict adherence to regulatory requirements in the manufacturing processes becomes even more critical. Mark Davis and the entire MSAT team at Boulder work constantly to examine and improve systems and processes to keep production running smoothly and maintain supply of these important medications.

Watch the full video below to learn more.