Process Validation

We offer a scalable process in order to help you prepare the clinical supply needed for commercial approval

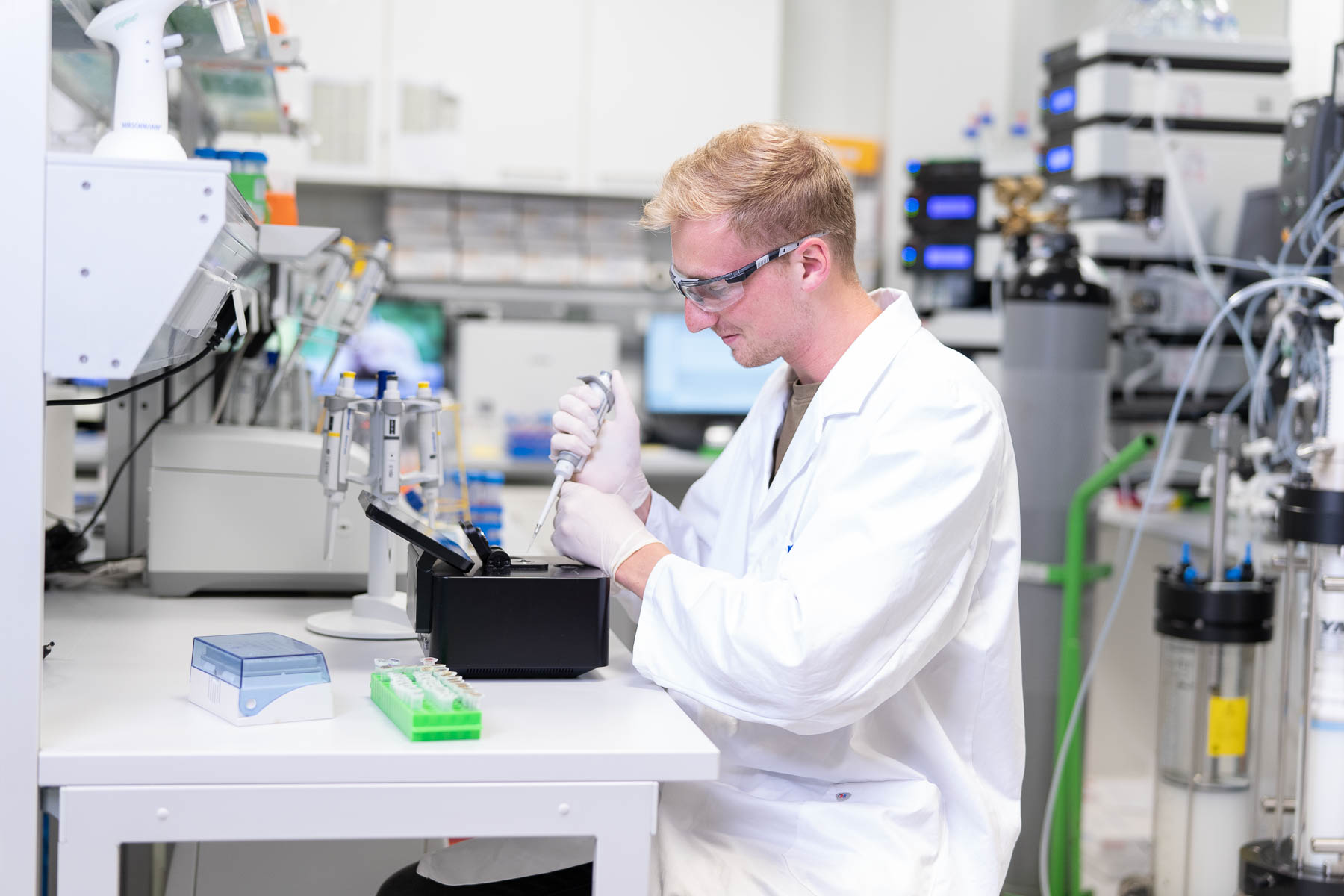

Drug substance process validation services

For customers preparing for commercial approval and post-commercial approval, Process Validation is a critical and significant set of activities. AGC Biologics has a well-defined approach with supporting Quality Systems to provide you with a targeted path through late-phase Process Validation. Our systems are based on the FDA’s Approved Guidance for Industry and ICH guidelines, using a risk-based lifecycle approach, and consist of three basic stages with supporting validation activities.

Got a project? Let's talk.

Stage 1

Process Design

- Identification of critical quality attributes and critical process parameters

- Risk assessments

- Process control strategy design

- Bench-scale model qualification

- Bench-scale process characterization/DOE studies

Stage 2

Process Performance Qualification (PPQ)

- At-scale PPQ campaign

Stage 3

Continuous Process Validation Program

Assess reliability, confidence, inter & intra batch variation uncertainties in PPQ sample size selection

This article details two statistical methodologies for calculating the necessary number of process performance qualification (PPQ) runs: the tolerance interval (TI) method and the process capability (PpK) method.

Download the whitepaper to read more.

DownloadFill out the form to access "Assess reliability, confidence, inter & intra batch variation uncertainties in PPQ sample size selection"

Stage 4

Supporting Validation Activities

- Mixing and hold time validation

- Extractables & leachables

- Impurity clearance

- API freeze / thaw studies

- Resin/membrane lifetime validation

- Virus clearance validation

- Raw material qualification

- Analytical method validation

- Cell line qualification

- Facility/utility/equipment qualification

- API shipping validation

Interested in learning more?

Contact our teamLet us know how to reach you and what information we can provide.

Quality by Design

The Highest-Standard Approach to Process Validation for Early and Late-Stage Projects

The Challenge —Develop and validate manufacturing processes for two novel molecules, one in phase 1 development and the other in phase 3.